Magnetic Seals

Magnetic seals are used when axial space is limited and operating conditions and customer requirements are beyond elastomeric or polymer seal capabilities.

Magnetic seals create an attraction, which eliminates the need for a spring and other items needed in face seal designs. This allows for our seals to be used in a variety of applications.

Seal Types

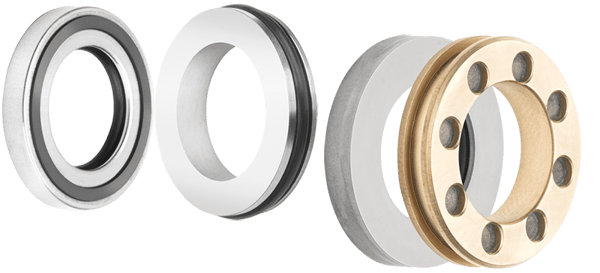

Type 45

When available space requires a shorter axial length, Type 45 seals are a viable option for lip seal replacement in demanding applications such as high-speed or high-pressure.FEATURES

- Face load 50-75% less than spring seal

- Short axial length

- Reduced friction on seal face lowers heat and wear resulting in longer seal lifespan

Parameters

- Pressure: Up to 50 PSI depending on size and operating conditions

- Speed: Up to. 17,000 sfpm

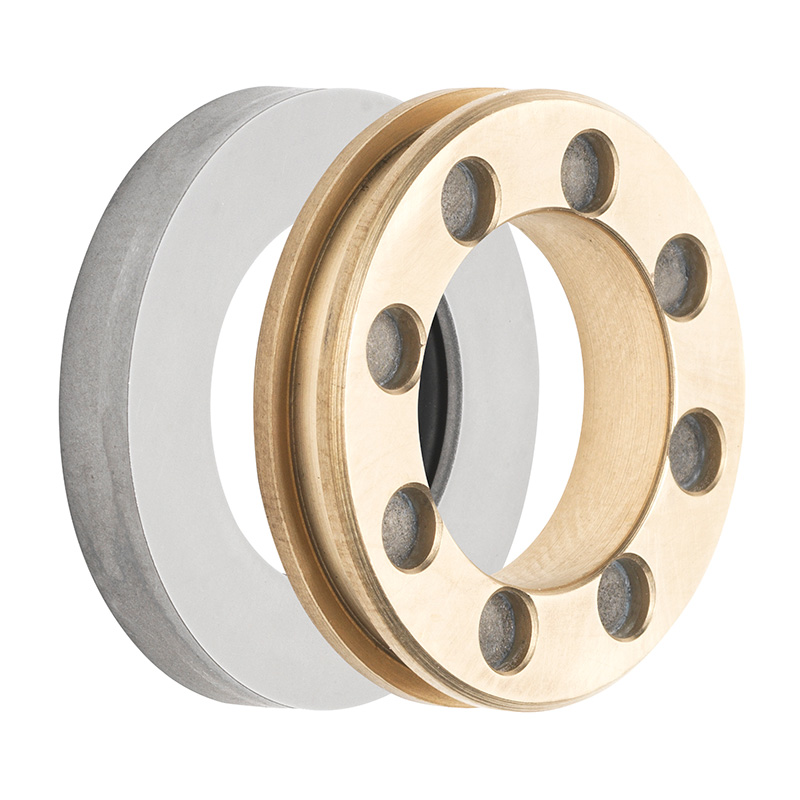

Type 40

Engineered to perform in high speed, vibration or altitude conditions, variable magnetic seals can replace lip seals where added life is required and leakage is critical. Also, because of the adjustability of the magnets, close alignment is not required as when using Alnico materials.

FEATURES

- Magnetic force (vs. mechanical) means less wear and longer seal life

- Ideal for high shaft speed applications

- Short axial length

PARAMETERS

- Pressure: Up to 75 PSI depending on size and operating conditions

- Speed: Up to. 17,000 sfpm

Custom solutions

While OEM seals suffice for some applications, many use cases require custom sealing solutions.

Whether you need a seal that meets specific performance requirements or can withstand extreme operating conditions, Ergoseal offers the in-house design and rigorous testing expertise to ensure your custom seal meets your precise specifications and performs in even the most demanding environments.