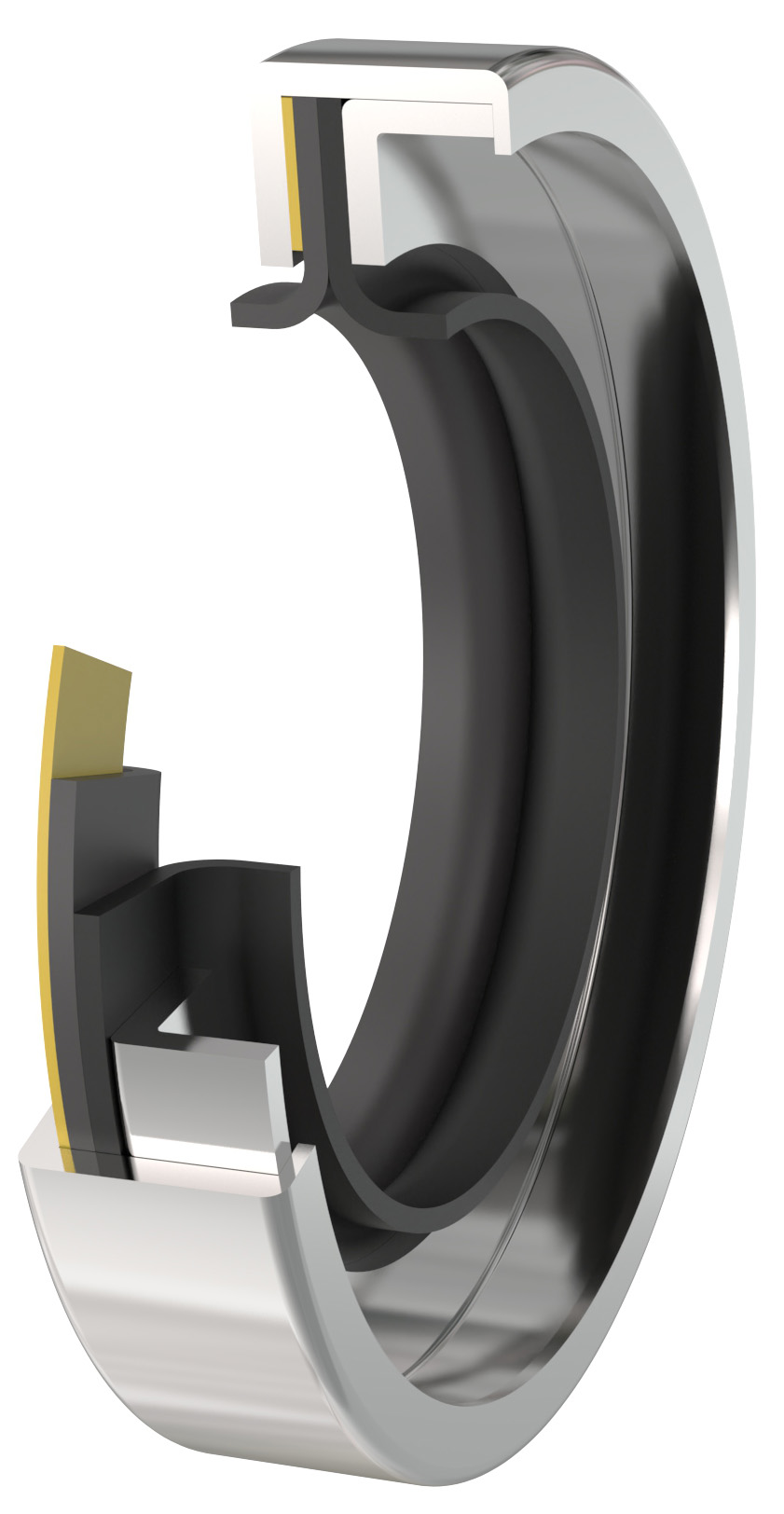

PTFE Lip Seals

PTFE lip seals are an alternative that bridges the gap between elastomer lip seals and mechanical carbon face seals, particularly in applications where higher pressure, speeds or other harsh conditions go beyond the capabilities of oil seals.

The typical size range is for shaft diameters from .125” (3 mm) to 10” (254 mm).

Seal Types

Applications

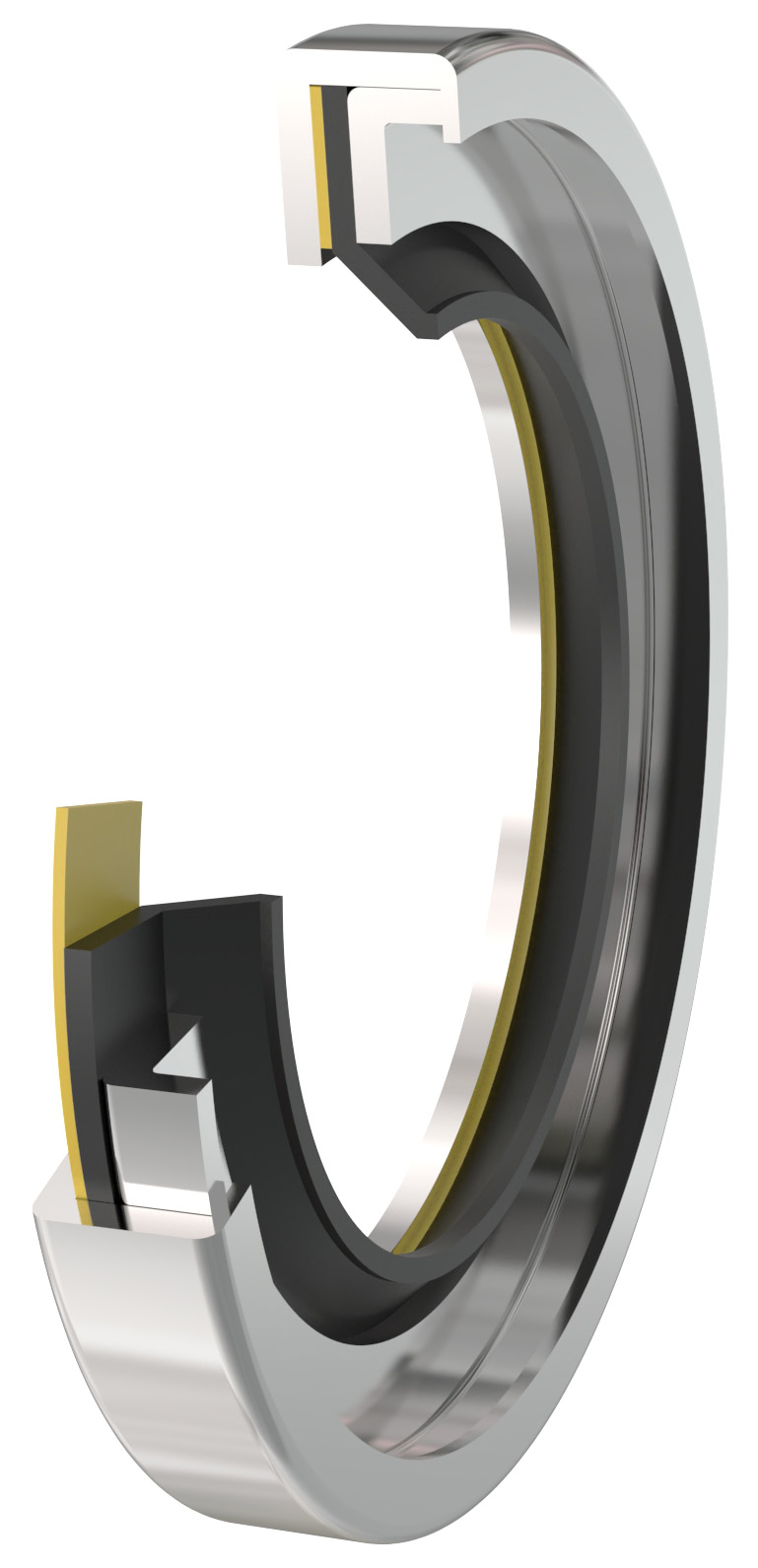

- General rotary applications

- Suitable for use in fans, pumps, compressors, gear-boxes, and engine crank case

Parameters

-

Pressures up to 125 psi (≤ 8 bar)

-

Temperatures from -40 °F to 500 °F (-40 °C to 260 °C)

-

Rotary speeds up to 5,900 fpm (≤ 30 m/s)

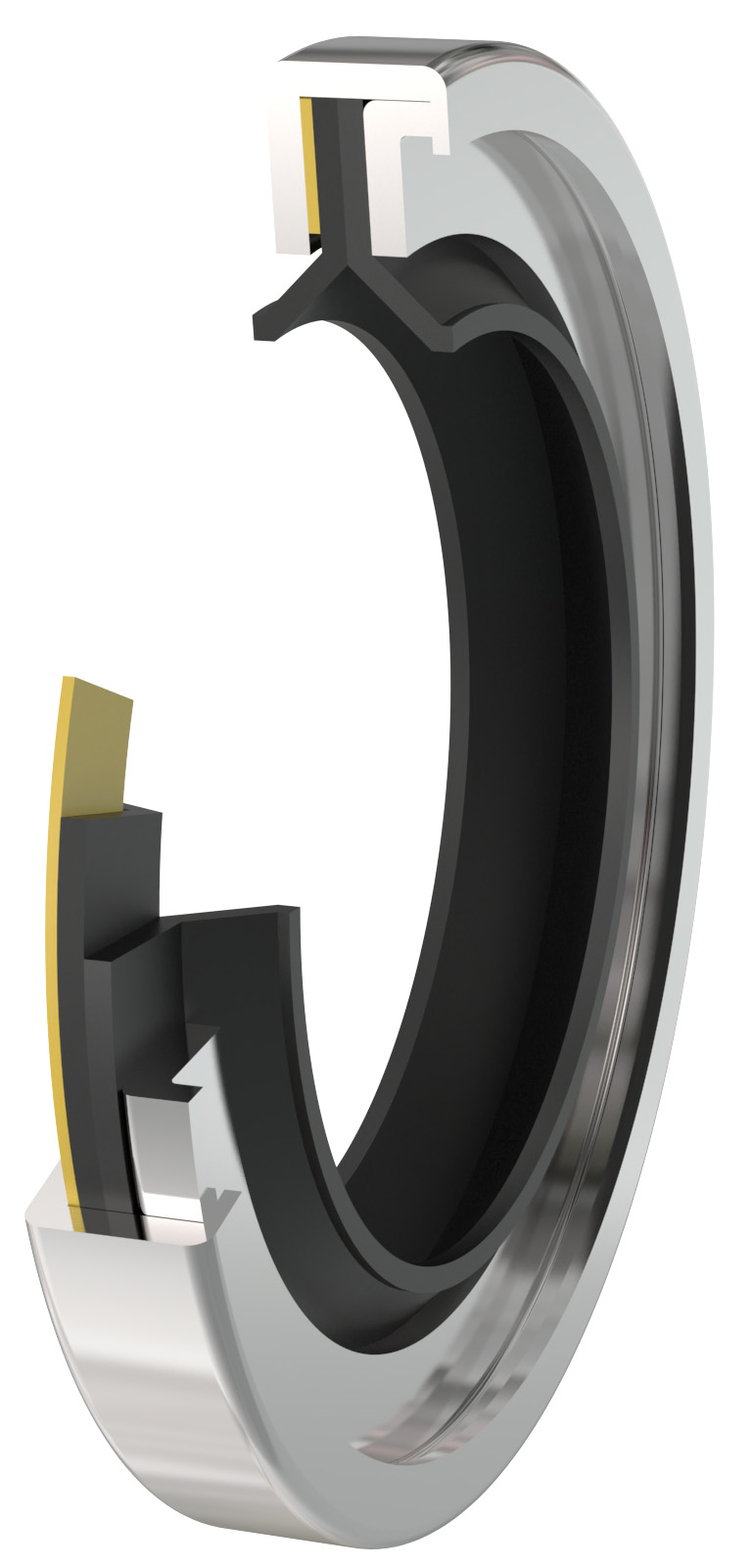

Applications

-

General rotary applications, low torque, dust and debris protection

-

Suitable for use in anti-friction bearing sealing applications

Parameters

-

Pressures up to 35 psi (≤ 2 bar)

-

Temperatures from -40 °F to 500 °F (-40 °C to 260 °C)

-

Rotary speeds up to 5,900 fpm (≤ 30 m/s)

Applications

-

General rotary applications, low torque, duel dust and debris protection

-

Suitable for use in anti-friction bearing sealing applications

Parameters

-

Pressures up to 35 psi (≤ 2 bar) both sides

-

Temperatures from -40 °F to 500 °F (-40 °C to 260 °C)

- Rotary speeds up to 5,900 fpm (≤ 30 m/s)

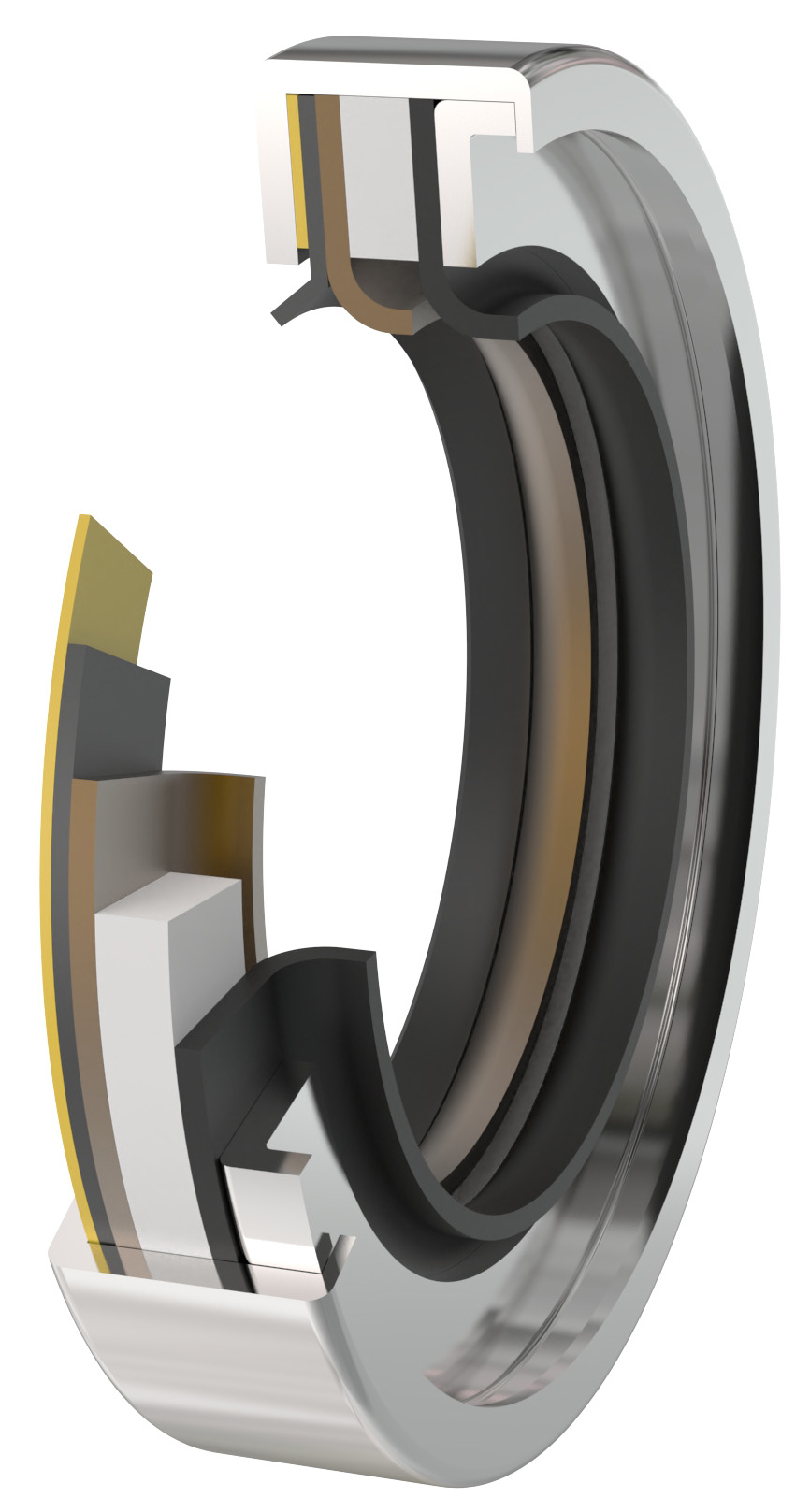

Applications

-

Higher pressure, low leakage, systems where backup is required

-

Suitable for use in hydraulic motors and hydraulic oil component applications

Parameters

-

Pressures up to 250 psi (≤ 17.25 bar)

-

Temperatures from -40 °F to 500 °F (-40 °C to 260 °C)

-

Rotary speeds up to 5,000 fpm (≤ 25.4 m/s)

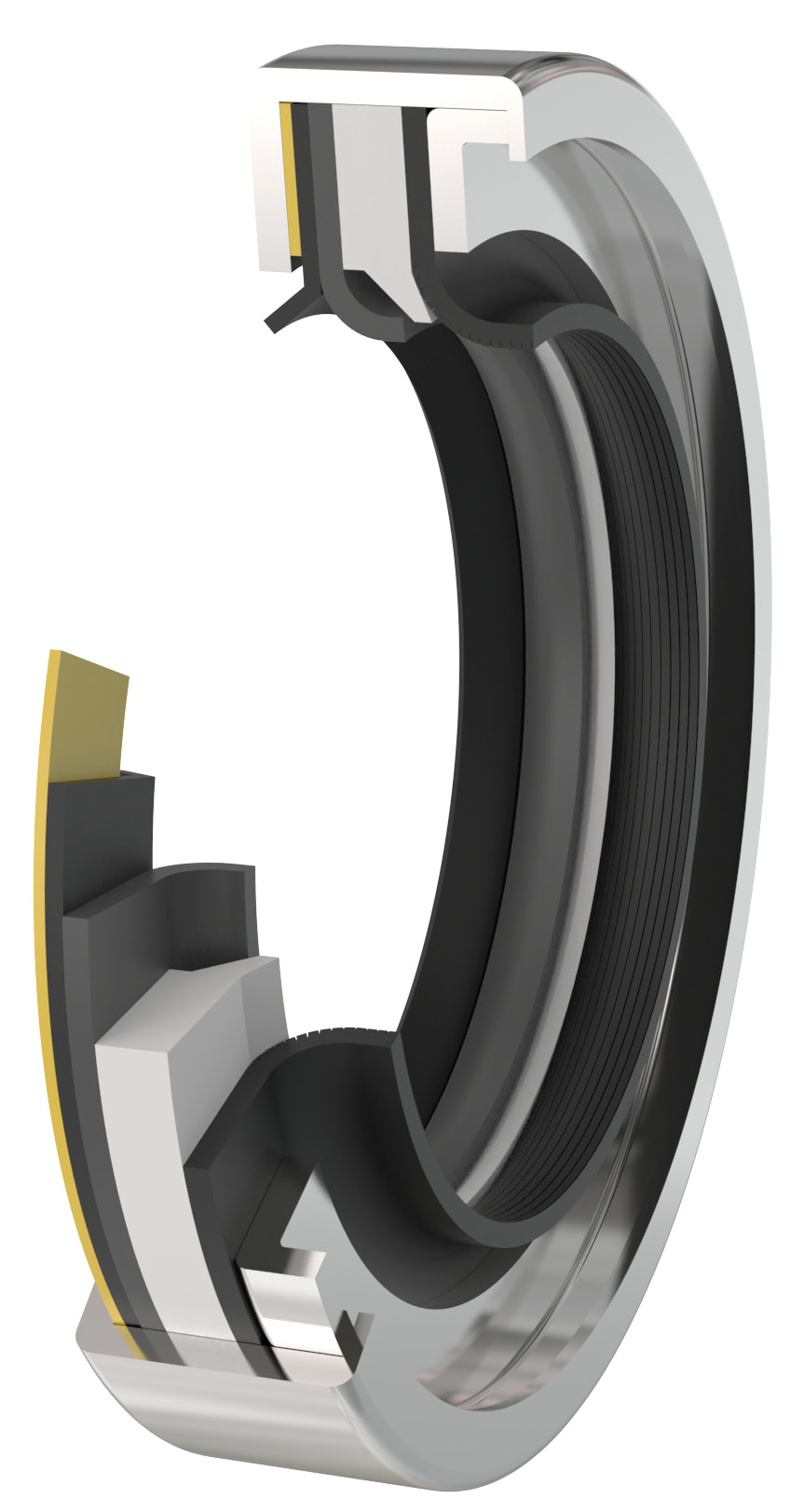

Applications

-

Super higher pressure, low leakage, systems where extreme backup is required

-

Suitable for use in hydraulic motors and hydraulic oil component applications

Parameters

-

Pressures up to 500psi (≤ 35 bar)

-

Temperatures from -40 °F to 500 °F (-40 °C to 260 °C)

-

Rotary speeds up to 5,000 fpm (≤ 25.4 m/s)

Applications

-

General rotary applications where dust or debris excluder is required on ATM side

-

Suitable for use in fans, pumps, compressors, gear-boxes, and engine crank case

Parameters

-

Pressures up to 500psi (≤ 35 bar)

-

Temperatures from -40 °F to 500 °F (-40 °C to 260 °C)

-

Rotary speeds up to 5,000 fpm (≤ 25.4 m/s)

Applications

-

Higher pressure, low leakage, systems where backup and exclusion is required

-

Suitable for use in hydraulic motors and hydraulic oil component applications

Parameters

-

Pressures up to 250 psi (≤ 17.25 bar)

-

Temperatures from -40 °F to 500 °F (-40 °C to 260 °C)

-

Rotary speeds up to 5,000 fpm (≤ 25.4 m/s)

Applications

-

Super higher pressure, low leakage, systems where extreme backup and exclusion is required

-

Suitable for use in hydraulic motors and hydraulic oil component applications

Parameters

-

Pressures up to 500 psi (≤ 35 bar)

-

Temperatures from -40 °F to 500 °F (-40 °C to 260 °C)

-

Rotary speeds up to 5,000 fpm (≤ 25.4 m/s)

Applications

-

Separating two different medias on both ends, opposite lip arrangements

-

Suitable for use in centrifugal applications

Parameters

-

Pressures up to 125 psi (≤ 8 bar) each side

-

Temperatures from -40 °F to 500 °F (-40 °C to 260 °C)

-

Rotary speeds up to 5,000 fpm (≤ 25.4 m/s)

Applications

- General rotary applications

-

Suitable for use in fans, pumps, compressors, gear-boxes, mixers

Parameters

-

Pressures up to 60 psi (≤ 4 bar)

-

Temperatures from -40 °F to 500 °F (-40 °C to 260 °C)

-

Rotary speeds up to 5,000 fpm (≤ 25.4 m/s)

Applications

-

General rotary applications, single lip with metal band

-

Suitable for use in fans, pumps, compressors, gear-boxes, mixers

Parameters

-

Pressures up to 60 psi (≤ 4 bar)

-

Temperatures from -40 °F to 500 °F (-40 °C to 260 °C)

-

Rotary speeds up to 5,000 fpm (≤ 25.4 m/s)

Applications

-

General rotary applications

-

Suitable for use in fans, pumps, compressors, gear-boxes, mixers

Parameters

-

Pressures up to 150 psi (≤ 10 bar)

-

Temperatures from -40 °F to 500 °F (-40 °C to 260 °C)

-

Rotary speeds up to 5,000 fpm (≤ 25.4 m/s)

Applications

-

General rotary applications, duel primary lips with metal band

-

Suitable for use in fans, pumps, compressors, gear-boxes, mixers

Parameters

-

Pressures up to 150 psi (≤ 10 bar)

-

Temperatures from -40 °F to 500 °F (-40 °C to 260 °C)

-

Rotary speeds up to 5,000 fpm (≤ 25.4 m/s)

Applications

-

General multipurpose rotary applications, dust and debris excluder

-

Suitable for use in fans, pumps, compressors, gear-boxes, mixers

Parameters

-

Pressures up to 60 psi (≤ 4 bar)

-

Temperatures from -40 °F to 500 °F (-40 °C to 260 °C)

-

Rotary speeds up to 5,000 fpm (≤ 25.4 m/s)

Applications

-

General multipurpose rotary applications, dual primary lips with dust and debris excluder

-

Suitable for use in fans, pumps, compressors, gear-boxes, mixers

Parameters

-

Pressures up to 150 psi (≤ 10 bar)

-

Temperatures from -40 °F to 500 °F (-40 °C to 260 °C)

-

Rotary speeds up to 5,000 fpm (≤ 25.4 m/s)

Applications

-

General multipurpose rotary applications, opposing sealing lips sealing two medias

-

Suitable for use in fans, pumps, compressors, gear-boxes, mixers

Parameters

-

Pressures up to 60 psi (≤ 4 bar)

-

Temperatures from -40 °F to 500 °F (-40 °C to 260 °C)

-

Rotary speeds up to 5,000 fpm (≤ 25.4 m/s)

Custom solutions

While OEM seals suffice for some applications, many use cases require custom sealing solutions.

Whether you need a seal that meets specific performance requirements or can withstand extreme operating conditions, Ergoseal offers the in-house design and rigorous testing expertise to ensure your custom seal meets your precise specifications and performs in even the most demanding environments.